Servicing & Maintenance of Tufting Guns

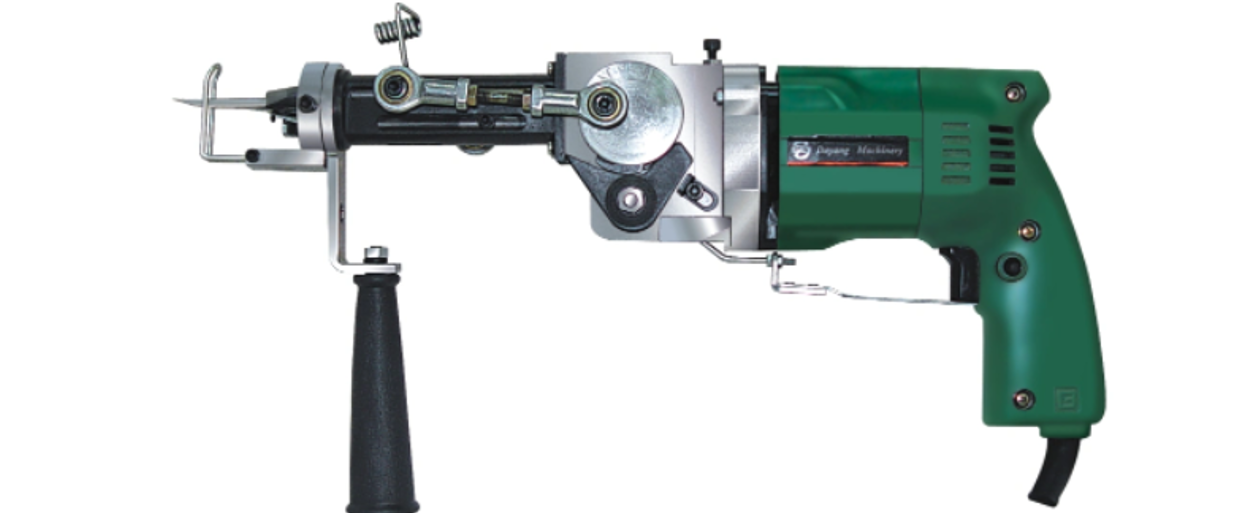

In the world of upholstery, tufting guns are a must-have tool for any upholsterer. They come in many different sizes and shapes, and it’s important to know which one is best for your project.

A tufting gun is also used to apply tufts or tacks to fabrics. A tuft is a type of fabric that has been cut into small strips and then sewn together at the centre point. This creates a fabric ball that can be used for decoration or as an accent on furniture or clothing. Tufting guns are used to hold these fabric balls in place while they are being secured with tacks or staples.

There are several different types of tufting guns, each with their own uses:

The Needle Tuft Gun

Needle type guns are designed for hand stitching, embroidery and appliqué. The needle threader is located at the top of the gun. It is used to thread the needle before stitching with the gun. The bobbin winding area is also located at the top of the gun, making it easy to wind threads onto bobbins without having to hold them in your fingers.

Hook-Type Guns

Hook type guns are used for topstitching, quilting, blind hemming and other processes that require a continuous stitch length. Hook type guns have a special hook attachment that allows you to stitch through multiple layers of fabric or leather without any problems.

Servicing Tufting Guns

It is important that you know how to service your tufting gun so that it will last longer and remain efficient.

You should also service your tufting gun if:

- The needle is not penetrating the fabric. This can be caused by a blunt needle or a damaged needle.

- The trigger isn't working correctly and won't fire the gun. This can be caused by a dirty trigger mechanism or a faulty trigger spring.

- You cannot push the handle down all the way and there is resistance when you try to pull it back up again (this problem could also be caused by a dirty or jammed needle).

- The needle doesn't fire when you pull back on the handle (again this could be caused by a variety of things).There are many things that you should look out for when servicing your gun:

-

Always check the condition of your needle before using it on your project; make sure that it has no cracks or breaks in it as this will cause damage to your fabric. If you notice any problems with it, replace it immediately!

-

Clean all parts of your gun thoroughly after each use; avoid leaving any dirt or materials inside of it as these can accumulate over time causing problems with the mechanism of the gun itself!

-

Make sure that all screws are tightened down completely before using your gun again so that no parts fall off during use and cause injuries or accidents while working with them in future.

Conclusion

If you are using a tufting gun to create decorative tufted areas, whether it be on carpets or fabric furniture, then you need to know how to take care of the different parts of the machine. You also need to know how to clean and repair your machine. The design and manual can tell you a lot about what needs to be done but sometimes those things are not always sufficient. In that case the only way left is to ask the dealer and the manufacturer for guidance.

The most important point is that tufting gun service and maintenance is worth it if you value your investment and future of your business. You can get the best tufting guns today at Alibaba’s online store with guaranteed affordable prices!